Home

/

DLO Diesel Locomotive Cable 2kV

/

373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

1

/

of

1

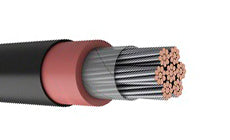

373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

SKU: SKU: NES1283X Download PDF

Select a gauge:

- 373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- Diesel Locomotive Cable 2000V

- 8 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 6 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 4 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 2 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 2/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 3/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 4/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 262 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 313 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 444 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 535 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 646 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 777 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 929 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1111 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 3 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 14 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 12 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 10 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 14 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 14 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 14 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 12 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 12 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 12 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 10 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 10 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 10 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 8 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 8 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 8 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 6 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 6 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 6 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 4 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 4 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 4 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 3 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 3 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 3 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 2 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 2 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 2 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 1 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 1 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 1 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 1/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 1/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 1/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 2/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 2/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 2/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 3/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 3/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 3/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 4/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 4/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 4/0 AWG 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 262 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 262 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 262 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 313 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 313 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 313 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 373 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 444 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 444 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 444 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 535 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 535 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 535 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 646 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 646 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 646 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 777 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 777 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 777 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 929 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 929 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 929 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 250' 1111 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 500' 1111 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

- 1000' 1111 MCM 2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable

Length:

FT

Enter footage in the box - Cut to one length. Min 1 ft - Max 10000 ft.

Unit price

/

per

Sold out

Shipping calculated at checkout.

IN STOCK Shipping Available

Free shipping on orders above $1000. *Wires and cables only.

Couldn't load pickup availability

Product Information

Also Known As:

373 Diesel Locomotive Cable, 373 DLO Cable, 373 DLO Wire, 373 Locomotive Cable, 373 Type DLO Cable, 373 DLO, 373 DLO Welding Cable, 373 DLO Heavy-Duty Cable

Conductor:

Fully annealed stranded tinned copper per AAR-598 and ASTM B 33 is resistant to corrosion.

Insulation:

Flexible premium-grade Ethylene Propylene (EP) Rubber

Jacket:

Black Chlorinated Polyethylene (CPE) resistant to acids, cuttings, scratches, and alkali.

|

Compatible with Manufacturer |

|

| Coleman item : |

167029 |

| General Cable item : |

5310.01373 |

| Omni Cable item : |

B83737 |

| Southwire item : | 1670290408 |

| Houston Wire item: | HW25437301 |

| Priority Wire & Cable : | 373-01DLO |

| AWC : | DLO-373.7 |

Resources

Applications

DLO electrical cable is used to transmit power within diesel engines, including industrial machines, wind turbines, cars, and train wagons. Diesel locomotive electrical cables power lead transmitter from the engine to the rotating wheels. Aside from the diesel engines, the cable can be used as a general building wire in mining equipment, industrial equipment, and motor leads thanks to its fire-resistant jacket and insulation. DLO is also suitable for sea-bonding locomotives and other marine applications. The temperature rating for continuous exposure is 90°C in wet/dry conditions.

Features

Standards:

ICEA S-95-685/NEMA WC 70

UL 44 TYPE RHH/RHW-2

c(UL) RW90

MSHA

RoHS

Allowable Ampacity For 373 MCM 600V/2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable: 588 Amps

ICEA S-95-685/NEMA WC 70

UL 44 TYPE RHH/RHW-2

c(UL) RW90

MSHA

RoHS

Allowable Ampacity For 373 MCM 600V/2KV DLO Diesel Locomotive Cable RHH/RHW Power Cable: 588 Amps

Specifications

Gauge: 373

No. Conductors: 1

Stranding: 931/24

Insulation Thickness: 0.090

Jacket Thickness: 0.020 inches

O.D. Inches: 1.043 inches

New Weight lb/1000FT: 1435 Lbs

No. Conductors: 1

Stranding: 931/24

Insulation Thickness: 0.090

Jacket Thickness: 0.020 inches

O.D. Inches: 1.043 inches

New Weight lb/1000FT: 1435 Lbs

Reviews