More gauges options

$0.97

$1.59

$2.19

$2.92

$3.64

$4.73

$5.37

$7.26

$8.63

$10.72

$11.72

$13.73

$15.93

$20.63

$22.14

$27.71

$38.56

$44.92

$2.21

$0.53

$0.72

$0.83

$127.50

$250.00

$460.00

$172.50

$335.00

$640.00

$202.50

$400.00

$790.00

$237.50

$460.00

$900.00

$387.50

$725.00

$1,350.00

$497.50

$975.00

$1,850.00

$535.00

$1,020.00

$1,940.00

$722.50

$1,420.00

$2,740.00

$907.50

$1,800.00

$3,580.00

$1,190.00

$2,375.00

$4,740.00

$1,337.50

$2,665.00

$5,310.00

$1,782.50

$3,215.00

$5,930.00

$2,130.00

$4,110.00

$8,120.00

$2,555.00

$5,060.00

$9,120.00

$2,755.00

$5,210.00

$9,820.00

$3,360.00

$6,470.00

$11,940.00

$3,732.50

$6,965.00

$13,730.00

$4,982.50

$9,265.00

$18,430.00

$5,010.00

$9,995.00

$19,940.00

$6,485.00

$12,970.00

$23,940.00

$9,480.00

$16,460.00

$31,920.00

$9,555.00

$17,210.00

$33,420.00

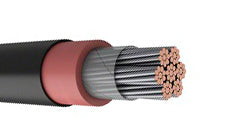

What is a DLO Cable?

DLO stands for Diesel Locomotive Cable. This is a type of rugged electrical transmission Cable that is used for diesel and oil locomotive operations, shipyard applications, mining tools and equipment, motor leads, power supply systems, oil drilling rigs and earth moving equipment. This 2kv DLO cable is specially constructed to operate in heavy duty and flexing applications, especially as a motor lead.

Applications:

DLO wire is primarily used in supplying electrical power in diesel locomotives, but with its properties it can serve in many other heavy-duty Applications.

• Shipyard applications

• Drilling rigs for oil and gas

• Conduit and raceway installations with power leads.

• Earth moving equipment and tools

• Mining tools and equipment

• Motor leads

• Power supply systems

Conductors:

Locomotive cable is constructed with flexible, fully annealed and stranded tin-plated copper.

Insulation:

EPDM Insulation

Standards:

• Type RHH/RHW-2, Underwriters Laboratory, UL 44

• NEMA WC 70 and ICEA S-95-685

• Its flame retardance is MSHA Approved

• UL listed under power supply

• RoHS compliant

| Size (AWG or KCMIL) |

Nominal Insulation Thickness (Inches) | Weight Per 1000ft Total (Lbs.) | Allowable Ampacity 90C (Amps) | Action |

| 8 Gauge DLO Cable | 0.060 | 110 | 83 | Add to Cart |

| 6 Gauge DLO Cable | 0.060 | 150 | 109 | Add to Cart |

| 4 Gauge DLO Cable | 0.060 | 220 | 145 | Add to Cart |

| 2 Gauge DLO Cable | 0.060 | 265 | 192 | Add to Cart |

| 1 Gauge DLO Cable | 0.080 | 420 | 223 | Add to Cart |

| 1/0 DLO Cable | 0.080 | 510 | 258 | Add to Cart |

| 2/0 DLO Cable | 0.080 | 570 | 298 | Add to Cart |

| 3/0 DLO Cable | 0.080 | 790 | 345 | Add to Cart |

| 4/0 DLO Cable | 0.080 | 930 | 400 | Add to Cart |

| 262MCM DLO Cable | 0.095 | 1130 | 458 | Add to Cart |

| 313MCM DLO Cable | 0.095 | 1295 | 514 | Add to Cart |

| 373MCM DLO Cable | 0.095 | 1545 | 574 | Add to Cart |

| 444MCM DLO Cable | 0.095 | 1820 | 642 | Add to Cart |

| 535MCM DLO Cable | 0.110 | 2125 | 725 | Add to Cart |

| 646MCM DLO Cable | 0.110 | 2560 | 815 | Add to Cart |

| 777MCM DLO Cable | 0.110 | 3050 | 910 | Add to Cart |

| 929MCM DLO Cable | 0.120 | 3500 | 1000 | Add to Cart |

| 1111MCM DLO Cable | 0.125 | 4350 | 1143 | Request A Quote |