Military and Aerospace Cable

Military refers to armed forces whereas aerospace means atmosphere or air vessel. Interested in aerospace and military grade wire and cables for military applications orflight applications? Make Military and Aerospace manufactured cables sold at Nassau Electrical your preferred choice and you’ll never regret your decision. This is because they are top quality cable products, which have been tested and approved to meet the threshold of the required quality standards.

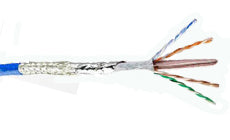

Military and aerospace cable manufacturing company designs harsh environmental adaptive products that can withstand extreme temperatures of up to 1093 degrees Celsius. Generally, they are made special to endure oil and fluid spills, moisture and abrasive resistant; often used in air, sea and land installation applications.